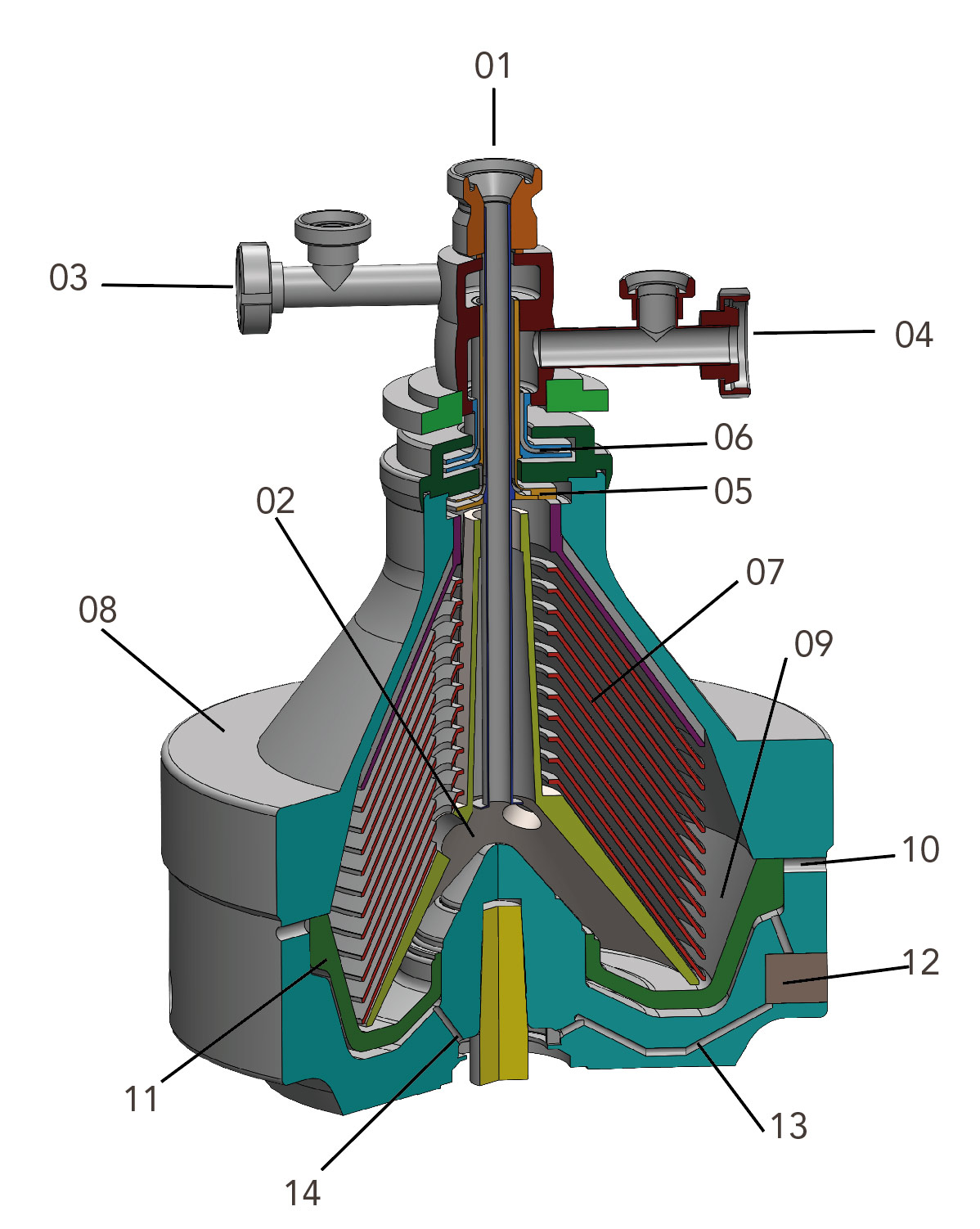

FAETURES DISC STACK CETRIFUGES

A sophisticated product

Whenever it is necessary to separate liquids or remove ultra-fine particles, and when traditional filtration methods reach their performance limits, disk stack centrifuges are exactly what you need to achieve the best results.

How a disc stack centrifuge works

- 1

Product inlet

- 2

Bowl distributor

- 3

Light phase outlet

- 4

Heavy phase outlet

- 5

Light phase centripetal pump

- 6

Heavy phase centripetal pump

- 7

Disc stack

- 8

Bowl

- 9

Solids chamber

- 10

Solids outlet

- 11

Sliding piston

- 12

Bowl valve

- 13

Operating water – opening

- 14

Operating water – closing

Separators

For the separation of mixtures of liquids with different densities and simultaneous elimination of solids – THREE-PHASE SEPARATION

Functioning

The product to be separated flows into the bowl through a feeding pipe and is gradually accelerated into the distributor, until the maximum bowl speed is reached.

It is then conveyed into the disc stack, where the liquid mixture is separated in two phases. The light phase flows towards the central part of the bowl, the heavy one towards the outside of the disc stack and both go up towards the upper part of the bowl where they are discharged by means of two centripetal pumps.

The solid substance is collected in the periphery of the bowl in the sludge chamber and from there is periodically ejected automatically. Partial and/or total discharges are possible. It is also possible to program the time interval between two discharges and their volume, as well as the washing of all internal surfaces before and after discharge.

Clarifiers

For the separation of fine solid particles from a liquid – TWO-PHASE SEPARATION

Functioning

The product to be clarified flows into the bowl through a feeding pipe and is gradually accelerated into the distributor, until the maximum bowl speed is reached.

It is then conveyed to the disc stack, where clarification takes place. The clarified liquid flows towards the central part of the bowl and goes up to the upper part of the same, from where it comes out by means of a centripetal pump.

Solid particles are collected in the periphery of the bowl in the sludge chamber and are periodically ejected automatically. Partial and/or total discharges are possible. It is also possible to program the time interval between two discharges and their volume, as well as the washing of all internal surfaces before and after discharge.